Generally speaking, film permeability test can be divided into three kinds: permeability testing for common inorganic gas, permeability testing for water vapor and permeability test for organic gas (organic vapor). The auto gas permeability test in out text refers to the film permeability test of common inorganic gas such as oxygen, carbon dioxide and nitrogen. This article attempts to give a brief analysis and comparing for the methods of film auto gas permeability testing.

1.Auto gas permeability test method

At present, most of the test methods employed by auto gas permeability testers are either differential pressure method or equal pressure method. These methods are based on different test principles and their test conditions also vary significantly.

1.1 Differential Pressure Method

Vacuum

Testing gas

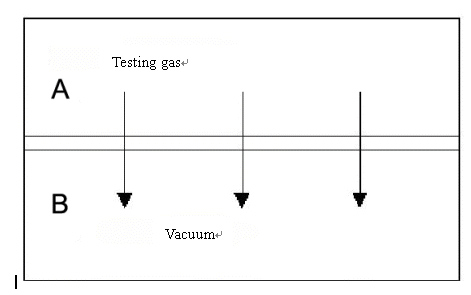

Fig 1. Illustrative diagram of vacuum testing method

The vacuum process is the most representative one of differential pressure method. In this method, (see fig 1) the permeation cavity is divided into two independent parts by the sample package. Vacuate the two sides and then fill one side (side A is the high pressure side) with testing gas of 0.1Mpa(absolute pressure) and the other side keeps the vacuum state. Testing gas between the two sides will form a pressure difference of 0.1Mpa. The testing gas transmits through the film into the low-pressure side and causes a pressure change there. Trough the following formula ( offered by ISO 15105-1 ) , gas transmission rate (GTR) can be calculated with a high precision vacuum gauge. The result unit is cm3/m2 · 24h · 0.1Mpa.

Vc represents the volume of low-pressure side

T is the test temperature ( thermodynamic temperature )

A is the effective transmission area

dp/dt is the pressure variation on low pressure side per unit time after the transmission becomes stable

R is the gas constant.

There are many testing standards about the vacuum process, for example ISO 2556 , ISO 15105-1 , ASTM D 1434 ( M method ), GB 1038 , JIS K 7126 ( A method ) .

In vacuum process, the pressure difference of 0.1Mpa between the two sides is realized with negative pressure difference principle. There is no doubt that the principle of positive pressure difference, which is a method for measuring pressure difference too, can also be used. The most commonly used method of positive pressure principle is the volume method. By volume method, there is no need evacuating the cavity and keeping the vacuum state. Therefore it reduces the difficulty of instrument manufacturing and permeation test. Correspondently, the cost of instrument manufacturing will be reduced comparing with that of the vacuum process. Relating standard is ASTM D 1434 ( V method ) .

1.2 equal pressure method

Fig 1. Illustrative diagram of sensor testing

Chemical sensor testing is the only method presently used in equal pressure method of permeation testing. It is mainly used for oxygen permeation testing. The testing principle is (see fig 2): use the package to divide the permeation cavity into two independent airflow systems with one side being the flowing testing gas (A can be pure oxygen or mixed gas of oxygen) and the other side being the flowing dry nitrogen gas (B). The pressure of the two sides is equal but oxygen partial pressure is different. Under the function of oxygen concentration difference, oxygen transits through the film and divert into the sensor by nitrogen carrier gas. Oxygen gas transmission rate ( O2 GTR ) of the package can be calculated through the oxygen quantity which is accurately measured by the sensor in nitrogen carrier gas . This method can test the uncalibrated oxygen transmission rate. the commonly used measuring unit is cm3/m2 · d. Calculating formula of O2 GTR offered by the standard ISO 15105-2 is that

- Where U is the output signal of zero voltage in testing.

- U 0 is the signal for zero voltage.

- p a is the environment atmospheric pressure

- p 0 is the oxygen partial pressure in testing gas.

- A is the effective transmission area.

2. Comparison of the two methods

For differential pressure method and equal pressure method, the test principle and test condition are different. they result units is also different from each other(the unit of differential pressure method is cm3/m2 · 24h · 0.1Mpa and that of equal pressure method is cm3/m2 · d ). Theoretically speaking there is no comparability between the uncalibrated data obtained from the two methods. But the comparison becomes possible after calibrating the instrument of equal pressure method with standard film and using that corrected factor in the formal testing.

With the supporting of film technology and theory, differential pressure method has been used as the basic method and it is commonly used in scientific research and testing institutions. The salient feature of this method is that it has no choice for testing gas and has a good versatility for different testing gas. The technology progress of vacuum gauge as well as the application of vacuum technology to instruments has improved testing accuracy and data repeatability of the instrument greatly. The volume method also has a good versatility for testing gas.

The sensor testing method appeared as oxygen detector technology is constantly maturing. Corrected factor of the instrument is not always effective and needs to be periodically calibrated as required because the sensor used belongs to the consuming type. And the sensor must be changed when it deteriorates to a certain extend. Sensor made by different manufactures has a different service life. In normal condition, the oxygen sensor of Labthink TOY-C1 has a service life of 12 to 30 months, which is relatively long.

3.Conclusion

Gas permeability testing is one of the indispensable parts in present material and quality testing of flexible package. With the rapid development of science and technology, instruments using different testing methods is constantly renovating and updating. The testing precision is continuously improving and the function of testing and inspecting is diversifying. For example, Labthink VAC-V1 has a temperature controlling function from 5 °C to 50 °C . TOY-C1 can offer a fully functional oxygen permeability testing for packages.